Wire ropes are an essential supply for rigging safety, but do you know how wire rope is classified? Do you know how to properly store your rope to increase its lifespan? Today on toolbox talks, we will discuss all things wire rope!

Commonly used in roofing applications, wire ropes are strands of wire woven into complex patterns that twist around a wire or fiber core to form a composite rope. They are reliable, but their strength varies: it is dictated by the number of individual wires, their size, and the wrapping configuration. This article explains basic rope classification and best practices for taking care of wire rope.

How is rope classified?

Rope classification is presented in the form “A x B.” A is the number of strands wrapping around the core, and B represents approximately the amount of wires in each strand. B is not an exact number. There is a range for each classification. For example, 6 X 19 rope will have precisely 6 strands wrapping around the core, but they can have between 15 and 26 wires per strand.

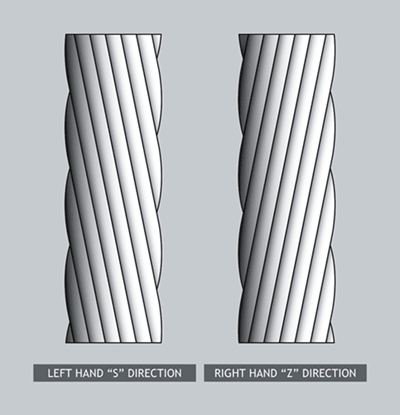

Woven wire ropes have a left or right lay that causes the rope to spool flat onto a hoist or crane drum. It is effortless to determine which lay your rope has: If you run your finger across a strand from top to bottom, the direction your finger travels indicates whether it is a left or right lay.

How to Care for Your Rope

Proper care and maintenance are necessary to maintain the longevity of your rope. Below are our favorite practices for preserving rope integrity.

- Store inside when possible. Harsh weather causes strands to wear rapidly. Extreme cold and heat jeopardize the interior structure of the wire rope, causing decay. In a worst-case scenario, the wire rope could snap under a heavy load. Avoid this by having a clean, dry area indoors for storage. We recommend using racks to prevent unnecessary damage from equipment or vehicles running over the rope.

- Avoid corrosive materials. Corrosive liquids and vapors are detrimental to the integrity of wire rope. If you work in areas with strong chemicals that can degrade metal, take care to store your rope in an area far from spills or splashes. If corrosive chemicals spill on a wire rope, it should be retired immediately.

- Never remove lifting capability tags. Ropes must be tagged with their lifting capabilities to ensure proper and safe use. If a rope isn’t labeled, remove it from service immediately. When untagged, it is possible to unknowingly go beyond the rope’s lifting capacity, causing the rope to tear or snap. Ropes broken under stress can cause severe injury and damage.

- Inspect before use. It is crucial to inspect wire ropes before each shift in which the wire rope will be used. A competent person should perform these inspections, and they must include a detailed observation of the rope running and standing. Look for distortion of the rope structure, corrosion, heat, electrical damage, and incorrectly placed end connections.

- Know when it’s time to replace. Even if you take excellent care of your wire rope, the time will come when it must be replaced. Small tears and excess wear can reduce a rope’s ability to maintain its lifting capability. So how do you know when it is time to retire a wire rope?

Replace a wire rope if any of the following exist:

- Excessive broken wires such as six or more in one lay

- Birdcaging

- Core Protrusion

- Kinking

- Flat appearance from friction

- Shiny appearance from wear

- Wear surpassing 1/3 the diameter

- Rust or discoloration

- High stranding and unlaying

Safe and effective wire ropes are a vital supply for many construction sites. Be sure that yours are safe, maintained, and ready for any job! Do you have any experience with wire rope care? Please share your stories below to help us spread the word about safe wire rope management.

Wishing you a happy and safe workplace,

Wryker’s Safety Team